The Role and Advantages of Hydraulic Systems in Dump Trailers

How hydraulic power enables efficient lifting and lowering of dump trailer beds

When it comes to moving heavy stuff, hydraulic systems really shine because they push around pressurized fluid to create force way beyond what hands or gears could handle alone. Take a regular old 12 volt hydraulic pump for example these things pack enough punch to hit well past 3000 pounds per square inch, which means they can lift weights over 20 thousand pounds without breaking a sweat. What makes hydraulics so great is how they transfer power through liquid instead of metal parts grinding against each other like chains do. This setup cuts down on all that annoying gear wear we see in traditional systems, plus operators get much better control when raising or lowering loads since there's no slipping or jerking involved.

Why hydraulics are preferred over mechanical systems in dump trailers

When it comes to strength versus weight, hydraulics beat out mechanical systems by about six to one. This means operators can start those full dump cycles with hardly any effort at all, just by moving a single lever. Think about it differently than having to crank manually or mess around with complicated gears - hydraulic controls really do make things easier for everyone involved. Plus, these systems have this closed loop design that absorbs shocks when loads aren't evenly distributed. Trailers experience roughly 40 percent less stress on their frames compared to old school direct drive lifts, which makes sense given how much wear and tear happens during regular use.

Key benefits: Power, control, and reliability in dump trailer operations

Hydraulic systems today work reliably around 98% of the time even when temps swing between -20 and 120 degrees Fahrenheit, which makes them pretty much essential equipment on construction sites and farms where conditions can get brutal. The proportional valves allow operators to position beds with pinpoint accuracy during those tricky partial unloads, something that matters a lot when working with heavy machinery. Meanwhile, automatic pressure relief valves act as safety nets against potential damage caused by sudden overloads. Since these systems have fewer moving parts compared to older models, most manufacturers recommend maintenance checks every 500+ hours instead of constantly tinkering with them. Plus, the self-lubricating components mean no more daily greasing headaches that plague traditional mechanical systems, saving both time and money in the long run.

Core Principles of Hydraulic Operation in Dump Trailers

Pascal's Law and Its Application in Dump Trailer Hydraulic Circuits

The hydraulics system in dump trailers works based on something called Pascal's Law. Basically, when pressure gets applied to fluid that's trapped inside, it spreads out evenly in every direction. So what happens is when the pump pushes against the hydraulic fluid, that pressure moves through all those hoses and valves right to where it needs to go, which is usually the lift cylinders. Take for example if there's about 1,000 pounds per square inch coming from the pump itself. That same amount of force ends up being felt throughout everything connected, which explains why even relatively small pumps can actually lift really heavy stuff like over 15 tons worth of material. What makes this whole thing work so well is that the bed moves consistently and predictably each time without wearing down parts the way gears or chains would typically do after repeated use.

How Hydraulic Pressure Is Generated and Transmitted for Bed Movement

Hydraulic pumps pull fluid out of the reservoir tank and then pressurize it using either gear mechanisms or piston arrangements. These systems typically generate flow rates ranging from around 5 to 15 gallons per minute, which is generally enough to lift a fully loaded bed within approximately 15 to 30 seconds depending on conditions. Once pressurized, the fluid moves along reinforced steel tubing toward the dual acting cylinders, converting that hydraulic pressure into actual movement as needed. Most modern sealed systems keep internal pressures somewhere between 2,000 and 3,000 pounds per square inch, ensuring consistent operation even when working across rough ground or when the trailer happens to be positioned at an awkward angle during loading operations.

Advancements in Pressure Efficiency and System Responsiveness

Today's equipment features load sensing pumps that actually respond to what the system needs right now, which cuts down on wasted energy by around 27% when compared with those old fixed displacement models according to Off-Highway Research from last year. The valves are electronically controlled too, making adjustments within milliseconds so everything moves much smoother. And don't forget about those synthetic ester fluids either they keep their consistency even when temps swing from as cold as -40 degrees all the way up to scorching 250 degrees Fahrenheit. All these upgrades mean modern trailers can handle about twice as many lifts before needing maintenance, plus they consume roughly 18 percent less hydraulic fluid overall. Pretty impressive stuff if you ask me.

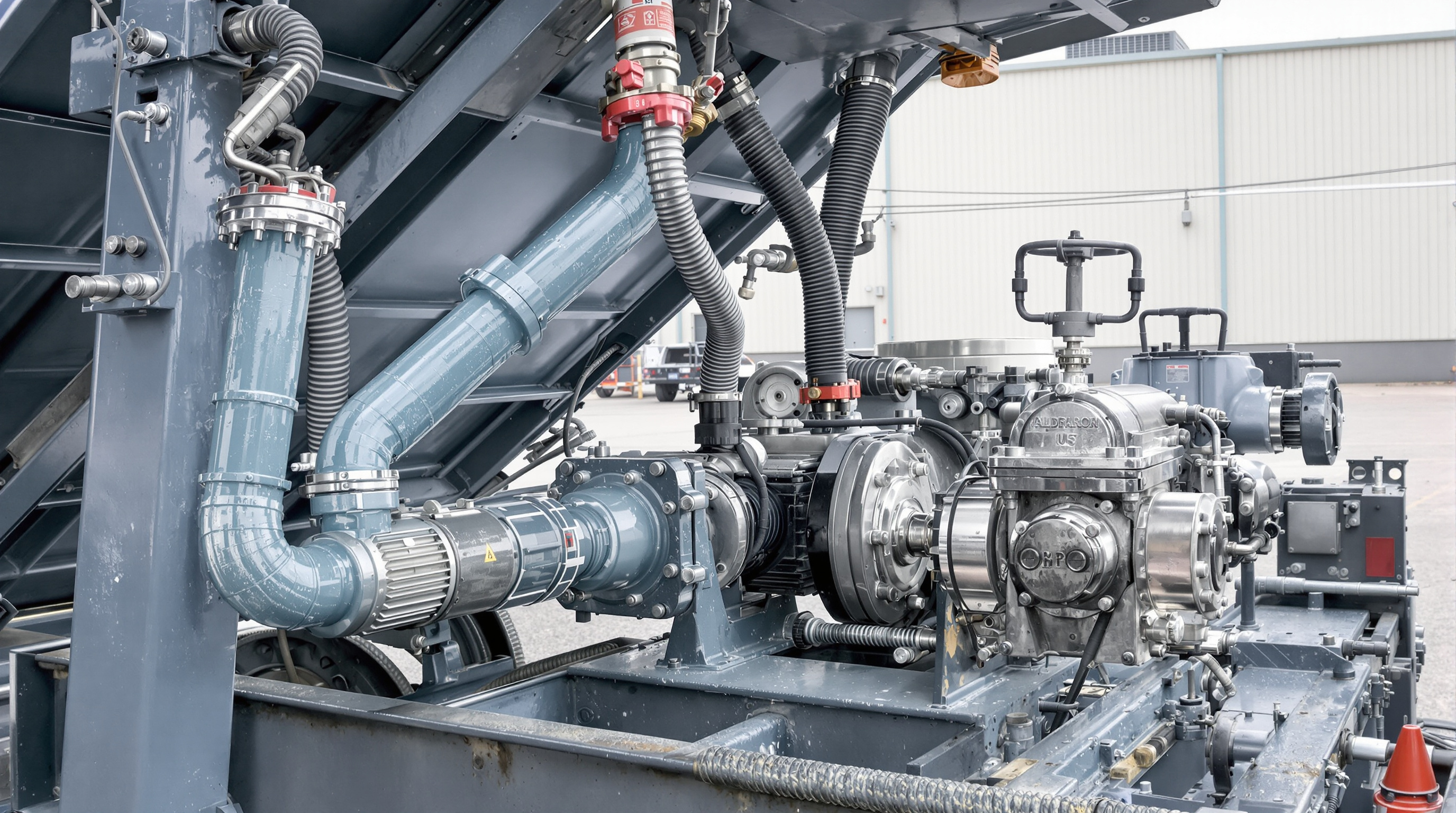

Essential Components of a Dump Trailer Hydraulic System

Main Components: Hydraulic Fluid, Pump, Cylinder, Valves, and Reservoir

Every dump trailer hydraulic system relies on five main parts working in harmony. The hydraulic fluid does double duty by transmitting power throughout the system and keeping those moving parts well lubricated. Synthetic fluids actually last about 40 percent longer when exposed to harsh operating conditions, which makes them worth considering for tough environments. Pumps, either gear type or piston driven, take mechanical energy from the engine and turn it into pressurized hydraulic flow. Then comes the cylinders that take all that pressure and convert it into actual lifting motion we see when the trailer bed tilts up. Directional control valves act like traffic cops directing where the fluid goes, and the reservoir sits there storing extra fluid while also helping cool things down as operations run hot. When everything connects properly, what we get is a sealed system that can handle pressures exceeding 3,000 pounds per square inch, something that's pretty impressive given what these systems need to accomplish day after day on job sites across the country.

Function of Hoses, Filters, Actuators, and Pistons in System Performance

Steel braided high pressure hoses move fluid between parts and are generally built to handle pressures four times what the system normally sees. The multi stage filters grab tiny particles down to 3 microns which matters because around three quarters of all hydraulic problems come from dirt getting into the system. These double acting pistons let for smooth movement both ways in and out, and the actuators keep everything positioned just right on the workbench. New self cleaning filters have cut down on maintenance requirements by about 30 percent especially when working in places like construction sites where dust is everywhere. Maintenance crews love this feature because it means fewer shutdowns for cleaning.

Case Study: Common Component Failures in High-Use Dump Trailers

Looking at data from around 200 heavily used dump trailers in 2023 showed some common problems happening again and again. The biggest issue was cylinder seals wearing out, which happened in nearly 4 out of every 10 breakdowns. These usually started failing somewhere between 18 to 24 months after installation. Then there was pump cavitation causing about 22% of all failures, mostly when operators didn't use the right type of hydraulic fluid during extreme weather conditions. Another 15% of problems came from hoses rubbing against their mounting points until they eventually leaked. The good news comes from newer trailers fitted with monitoring sensors that cut unexpected downtime by almost two thirds thanks to early warning systems for maintenance needs. This kind of proactive approach makes a huge difference in keeping operations running smoothly without costly surprises down the road.

Balancing Durability with System Simplicity in Component Design

Manufacturers enhance durability using grade 304 stainless steel in corrosion-prone areas while prioritizing field-repairable configurations. Simplified valve blocks with 30% fewer connections than industrial equivalents perform better in high-vibration settings. Modular pump assemblies allow quick replacements without full disassembly—a design proven to cut repair time by 45% in fleet maintenance studies.

Hydraulic Pump Types and Power Sources for Dump Trailers

How the Hydraulic Pump Drives System Operation

At the heart of any hydraulic system is the pump, which converts mechanical energy into fluid pressure to power all other components. This fundamental operation is based on Pascal’s principle, which states that pressure is transmitted uniformly throughout a confined fluid. Most dump trailers rely extensively on gear pumps due to their durability in handling dirt and debris, as well as their straightforward maintenance requirements. For more demanding applications that require higher power output, piston pumps are employed for their ability to generate significantly greater pressures. Recent fluid power industry trends from last year indicate that gear pumps account for approximately 62% of the dump truck installation market, owing in part to their dependable performance even in harsh and dusty environments. Many operators strongly prefer them based on years of experience witnessing the failure of cheaper alternatives in the field.

Power Supply Options: PTO, Electric, and Gas-Driven Pumps

Three primary power sources drive hydraulic pumps:

- Power Take-Off (PTO): Connects directly to the tow vehicle's transmission, best suited for frequent cycling

- Electric: Powered by the trailer's battery, ideal for light-duty use (<15 lifts per day)

- Gas-driven: Features an independent engine, providing high flow rates (up to 25 GPM) for remote or intensive operations

Field tests show gas-driven pumps maintain 94% efficiency in sub-freezing conditions, whereas PTO systems experience a 78% performance drop in the same environment.

Selecting the Right Pump Based on Dump Trailer Usage and Environment

Pump selection should align with GVWR and operational demands:

- Gear pumps are suitable for most standard trailers (<14,000 lbs GVWR)

- Piston pumps are recommended for tandem-axle units (>20,000 lbs)

- Electric pumps work well for urban deliveries with <8 daily lifts

In extreme cold (-20°F), vane pumps outperform gear models but require synthetic fluids. Industry data shows proper pump matching reduces hydraulic failures by 40% (Equipment Maintenance Report, 2023).

Types of Hydraulic Lifting Mechanisms and Maintenance Best Practices

Single-Acting vs. Double-Acting Cylinders: Performance and Use Cases

Single-acting cylinders use hydraulic pressure for lifting and rely on gravity for retraction, making them cost-effective and efficient for trailers with consistent load weights. Double-acting cylinders apply pressure in both directions, offering greater control and precision—ideal for handling unbalanced or variable loads in industrial applications.

Scissor Lift vs. Telescopic Lift: Differences in Efficiency and Application

Scissor lifts work great for getting things up vertically in tight spots where there's not much headroom, usually reaching around 12 feet high. These are often seen in places like warehouses or maintenance areas where ceiling height is limited. On the other hand, telescopic lifts focus more on extending horizontally and moving materials quickly between points. They really shine when transporting large volumes of stuff across distances. A recent study from last year showed that these telescopic models can dump loads about 18 percent quicker during gravel or sand hauling jobs compared to traditional methods. This speed advantage makes them particularly valuable for construction sites dealing with heavy materials day after day.

Hydraulic Cylinder Alignment and Lift Cycle Efficiency Benchmarks

Proper cylinder alignment reduces rod scoring by 37% (Fluid Power Journal 2022). Operators should verify parallelism within 0.002 inches per foot and monitor cycle times—well-maintained systems complete full dumps in 15–25 seconds, depending on bed size.

Maintaining Fluid Levels, Removing Air, and Bleeding the System

Check hydraulic fluid weekly using the ISO grade specified by the manufacturer. Bleed air from the system through cylinder bleed valves, especially after servicing or during seasonal temperature changes. Replace filters every 300–500 operating hours to minimize contamination risks.

Synthetic vs. Conventional Hydraulic Fluids: Pros, Cons, and Recommendations

Synthetic fluids perform reliably in extreme temperatures (-40°F to 250°F) but cost 2.3 times more than conventional mineral oils. For most dump trailers operating below 200°F, premium anti-wear (AW) hydraulic fluids offer sufficient thermal stability, oxidation resistance, and corrosion protection between service intervals.

FAQ

What is Pascal's Law and how does it apply to hydraulic systems in dump trailers?

Pascal's Law states that pressure applied to a confined fluid is transmitted equally in all directions. In hydraulic systems, this principle allows the consistent and predictable operation of dump trailer beds during lifting and lowering actions.

How often should hydraulic systems in dump trailers be maintained?

It's generally recommended to perform maintenance checks every 500 operating hours. This includes checking hydraulic fluid levels, bleeding the system to remove air, and replacing filters to avoid contamination issues.

What are the recommended power sources for hydraulic pumps in dump trailers?

The power sources include Power Take-Off (PTO) systems for frequent cycling, electric systems for light-duty use, and gas-driven systems offering high flow rates for remote or intensive operations.

What are the main components of a dump trailer's hydraulic system?

The main components include hydraulic fluid, pumps, cylinders, valves, and reservoirs, working together to manage hydraulic pressure and movement effectively.

What are the common causes of hydraulic system failure in dump trailers?

Common causes include cylinder seal wear, pump cavitation due to incorrect fluid usage, and hose abrasion leading to leaks. Monitoring sensors and early warning systems can help minimize unexpected failures.

Table of Contents

- The Role and Advantages of Hydraulic Systems in Dump Trailers

- Core Principles of Hydraulic Operation in Dump Trailers

- Essential Components of a Dump Trailer Hydraulic System

- Hydraulic Pump Types and Power Sources for Dump Trailers

-

Types of Hydraulic Lifting Mechanisms and Maintenance Best Practices

- Single-Acting vs. Double-Acting Cylinders: Performance and Use Cases

- Scissor Lift vs. Telescopic Lift: Differences in Efficiency and Application

- Hydraulic Cylinder Alignment and Lift Cycle Efficiency Benchmarks

- Maintaining Fluid Levels, Removing Air, and Bleeding the System

- Synthetic vs. Conventional Hydraulic Fluids: Pros, Cons, and Recommendations

+86-13969627783

+86-13969627783